Dura-Bar: An Alternative to Castings

Overview

Dura-Bar continuous cast iron is a high quality alternative to castings. With Dura-Bar, there is no sand or carbides, so there are no defects like those typically found in castings and Dura-Bar comes with a unique Zero Defect Guarantee.

Dura-Bar's material consistency stems from the continuous casting process used to produce it. Continuous casting involves pulling bars through a graphite die at the bottom of a crucible filled with molten iron. Dross, slag, and other impurities float to the top of the crucible and never make it into the cast bars.

Besides eliminating defects, continuous casting also yields an especially fine-grained microstructure which permits faster machining and extended tool life. This boosts throughput and lowers a manufacturer's cost per part. It also permits better surface finishes.

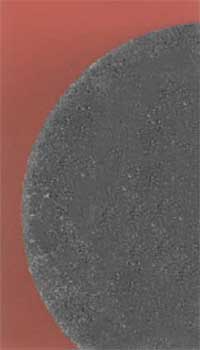

Dura-Bar

Sand Casting

Dura-Bar material has a consistent fine-grained microstructure; free from sand and carbides unlike sand castings.

Example Application: Pump Housing

Casting's Problems

- Inconsistent availability and delivery

- Low quality material

- Parts in varying lengths

Solutions and Benefits

- Reliability and consistency from a stable manufacturer

- Zero-Defect guarantee

- No pattern needed

- Immediate availability from a Dura- Bar distributors (over 100 locations)

- Improved machinability

- Total part cost reduction