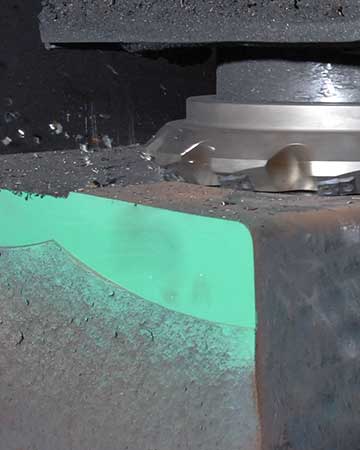

Milling

Dura-Bar offers cold finished milling as an added service for rectangular and square bars. Many sizes are available from stock, and additional sizes can be custom ordered.

Some benefits of close tolerance bars include:

- Eliminating rough milling operations

- Sizing or locating for fixtures and tombstones

- Removing the as-cast surface to increase insert life

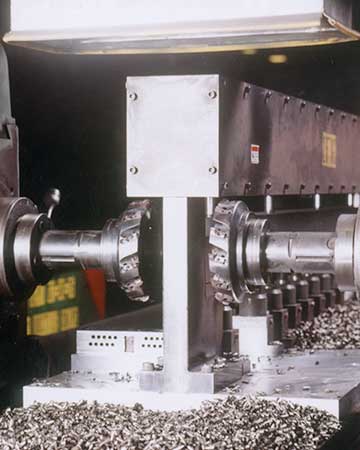

Duplex Milling

Duplex milling offers the advantage of milling two sides of a product in one operation for additional cost efficiencies.

Capabilities

| Characteristic | Details |

|---|---|

| Surfaces Milled | 2 or 4 side |

| Max. As-Cast Size | 6.250" x 6.250" * |

| Min. Milled to Size | 2.000" x 2.000" |

| Size Tolerance Up To | +/- 0.005" |

| Square, Parallel and Flat | Within 0.010" in any 6.000" section |

| Surface Finish | 125 RMS maximum |

| Bar Length | 72" |

| Coating | Milled bars coated with a rust prohibitive |

* Please contact Dura-Bar if you require larger sizes

Planer Milling

Planner milling can treat one, two, three or four sides of a product to meet specific customer needs and applications.

Capabilities

| Characteristic | Details |

|---|---|

| Surfaces Milled | 1, 2, 3 or 4 sides |

| Min. As-Cast Size | 4.500" x 4.500" |

| Max. As-Cast Size | 25.000" x 25.000" * |

| Min. Bar Length | 54" |

| Max. Bar Length | 102" |

| Square, Parallel and Flat | Within 0.010" in any 6.000" section |

| Surface Finish (RMS) | Not milled to any RMS finish maximum |

| Coating | Milled bars coated with a rust prohibitive |

* Please contact Dura-Bar if you require larger sizes

Size Tolerance

| 2 Surfaces | 3 Surfaces | 4 Surfaces |

|---|---|---|

| 0.062" / -0.000" | 0.030" / -0.000" | 0.030" / -0.000" |

| 0.062" / -0.000" | 0.062" / -0.000" | 0.030" / -0.000" |